What machine is used to make tea bags?How does a tea bag machine work?

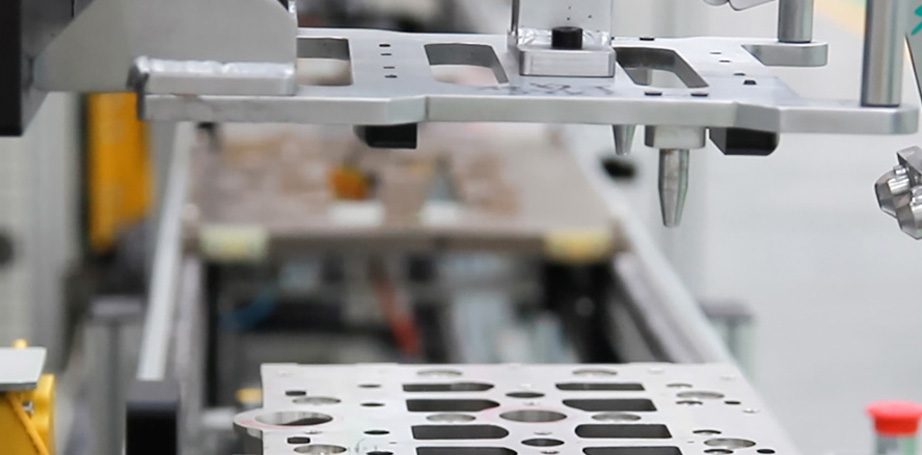

The tea bag is a convenient, healthy, and popular drink among consumers. The tea bag packing machine is one of the most important equipment in the producti...

Stand-up pouch with zipper, Flat pouch, Flatpouch with hole, Boxpouch,Box pouch with hole, Box pouch with valve, Box pouch with zipper, Gusset pouch

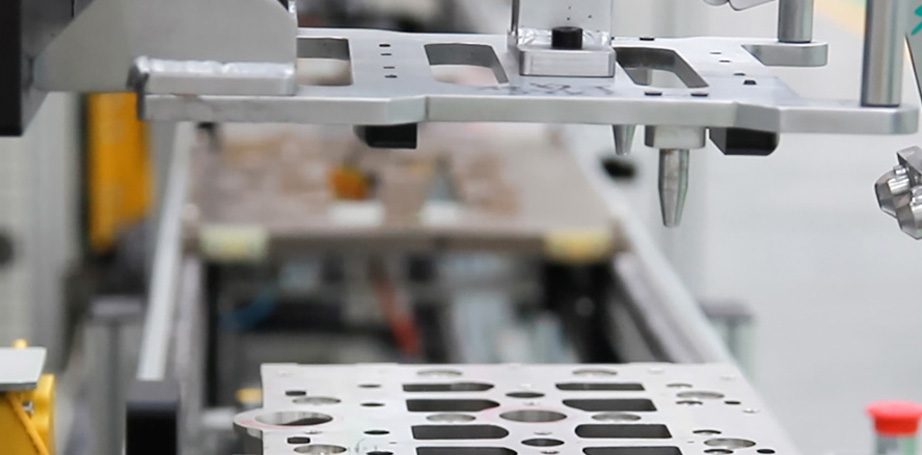

1. Horizontal Infeed conveyor suits for bags with zipper, max. put 300 pcs each time.

2. PLC adjusts bag width clamping: Only needs 2mins by auto PLC to adjust different bag width sizes.

3. Automatic lubrication system: PLC controls the lubrication time, and automatically lubricates the machine parts instead of by manual.

The pre-made pouch packaging machine is widely used for packaging various materials such as solids, powders, liquids, etc. in fields such as food, medicine, cosmetics, daily necessities, etc.

Mingyuan is a premade pouch packing machine factory with 11 years of professional experience in China. Automatic Prefabricated Bag Packaging Machine has the characteristics of reasonable design and convenient operation. It is suitable for irregular packaging shapes and measurement accuracy requirements.

Max Speed

Max Speed50 bp.m

Bag Size

Bag Size100 x 80 mm

350 x 200mm

Automatic 8 stations for pre-made bags packaging

Automatic Pick & Place bag infeed system

Siemens PLC control with touch screen operation

Multi-Language HMI

Date Coding

304 stainless steel frame

Pouch presence detection – no filling, no sealing

Various filling systems for powder, granule, liquid, snacks

Automatic deoxidizer & spoon feeding station

Date coding

herbal, or other customized products

Zipper opening & Sealing device

Collating discharge conveyor

Metal detectors

Checkweigher

Material infeed conveyor

| Model | MY8-100K |

| Mechanical station | eight stations |

| Packing bag type | self-supporting bag, four-side sealing bag, three-side sealing bag, paper bag and other composite bags |

| Packing bag size | W:80mm-200mm |

| L:100-350mm | |

| Package weight | 100-1000g |

| Packing speed | ≤45 bags/min (the speed is determined by the material itself and the filling weight) |

| Machine weight | 1100Kg |

| Voltage | 380V three-phase 50HZ/60HZ |

| Total power | 2KW |

| Compressed air consumption | 0.9m3/min (provided by the user) |

The laminated film, laminated paper film, aluminum foil film

Hanging hole, euro slot, carry handle, degassing valve, tear notch, zipper, spout

NEWS & BLOG

Mingyuan offers packaging machines that handle various types of packaging materials to meet your business' unique packaging needs. Whether it is fluid, granule, powder or other packaging solutions, Mingyuan can meet your needs.

The tea bag is a convenient, healthy, and popular drink among consumers. The tea bag packing machine is one of the most important equipment in the producti...

After the transformation and innovation of the equipment, the pyramid tea bag packing machine can now package black tea, green tea, oolong tea, jasmine tea...

A liquid packaging machine is an industrial device used to automatically fill and seal containers with liquid products.Commonly used in food and beverage, ...

When selecting a sauce packing machine for tomato sauce or ketchup, specifically a small automatic one, it's important to consider the following factors:Pa...

Choosing a packing machine requires careful consideration of several factors to ensure that it meets your specific packaging needs. Here are some key steps...

Attention, so what should the powder packaging machine pay attention to? Next, the manufacturer of the Mingyuan powder packaging machine will give you a de...